First-of-its-kind engineering feat amidst the fjords

Building the world’s longest undersea cable, to allow the UK to share zero carbon energy with Norway, has brought some challenges. Read more about how we engineered smart solutions to deal with tough terrain and fishing lakes.

Construction of the world’s longest subsea power cable has passed its halfway point, achieving a major engineering feat on the way. The super-sized cable, known as an interconnector, will span 720km on completion, linking the electricity grids of the UK and Norway.

It will allow us to access more Norwegian hydro-energy, helping the UK on its journey to reaching net zero by 2050, as well as enabling us to trade our own excess clean energy. When the interconnector, known as North Sea Link, is operational in 2021, the 1.4 gigawatt electricity cable will let the UK import enough zero carbon energy to power up to 1.4 million homes.

Engineering solutions

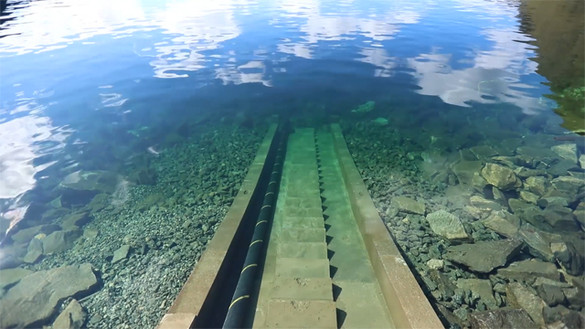

Alongside our joint venture partners, Norwegian power system operator Statnett, the project has involved us facing the challenge of manoeuvring the cable through a beautiful, unspoilt lake, which crucially cannot be accessed by the size of vessel usually required for cable laying.

The operation is the first of its kind on this scale in Norway.

To overcome this, the team transported materials piece-by-piece to build their own custom-made floating platform. The operation is the first of its kind on this scale in Norway and the construction of the platform had an average of 25 people working on it daily over the course of 11 days. This unique operation in Suldalsvatnet marked the start of the cable laying on the Norwegian side.

Working at depths of up to 210 metres, the laying of the 2.8km parallel subsea cables was then carried out from the 43 x 15 metre platform, which is equivalent to the size of two tennis courts. The platform held all the necessary equipment that is usually found on offshore cable laying vessels.

Tough terrain

Nigel Williams, our Construction Director for the North Sea Link project, says: “The engineering that has taken place to lay the cables is remarkable. The difficult terrain and the depth of the waters, and all this while operating during a pandemic, has made it extremely challenging.

“Nevertheless, we’ve powered through and remained on track with our project timelines. Even though this has never been done before, we responded to the challenge and made it happen.”

Caring for the surrounding environment was particularly important.

Caring for the environment

Amidst the majesty of the fjords, caring for the surrounding environment was particularly important. “The prospect of heavy construction in this area is daunting, but the partnership with the Norwegians was hugely reassuring as they have extensive knowledge and experience of working in this part of the world and are used to these challenges,” explains Nigel. For example, because salmon fishing is extremely important in Norway, the water quality in the fjords had to be protected by erecting a silt curtain to trap sediment and prevent it from clouding the water.

Next steps for this Nordic-UK connection

Following this major engineering feat, the next milestone is to lay the cable out from the fjords in Suldal to the North Sea, which will happen this summer. By 2021 the two parallel cables between Cambois, Northumberland in the UK and Kvilldal, in Norway will have been completed, making North Sea Link the longest subsea power cable interconnector in the world.